Analyzers for your interests

Optoseven develops and manufactures instrumentation and analyzer systems for real-time detection of liquids. The company exploits the latest developments in optoelectronics and engineering to meet our customers’ needs. Main application areas are the control and monitoring of industrial processes.

Optoseven analyzers can monitor multiple species simultaneously, at concentration levels ranging from percent to micrograms per cubic meter and beyond, depending on the application.

Solutions

Waste Water

Reliable monitoring and control through the process with low maintenance cost. Optimized process control in order to cut operating costs and fulfill requirements.

Clean Water

Accurate monitoring from raw to purified water with the single analyzer unit. Reduced process interruptions by better control of filtration stages.

Industrial Processes

Continuous measurement of custom components in all sectors of industry. Material saving by better process control and product quality monitoring.

Natural Water

Comprehensive analytics of natural waters. Round the year monitoring of industrial loaded water systems or the impact of the climate to the waters.

Tailored Systems

Cost effective and rapid way to design and realise custom analyzers and monitoring systems. With the aid of Optoseven professionals your needs are fulfilled.

Realible multicomponent liquid analysis.

You can measure it.

Optoseven’s new innovative approach

Optoseven employees have a long experience of developing and manufacturing gas analyzers for emissions monitoring, where reliability is mandatory because of strict regulations. Today waters are still often analysed from the grab samples, which is not the best way to monitor and control the process.

Optoseven develops the online liquid analyzers using the embraced know-how and innovations. By combining the benefits of reliable and continuous emissions monitoring and by keeping in mind the same standards of reliability as in the laboratory measurements.

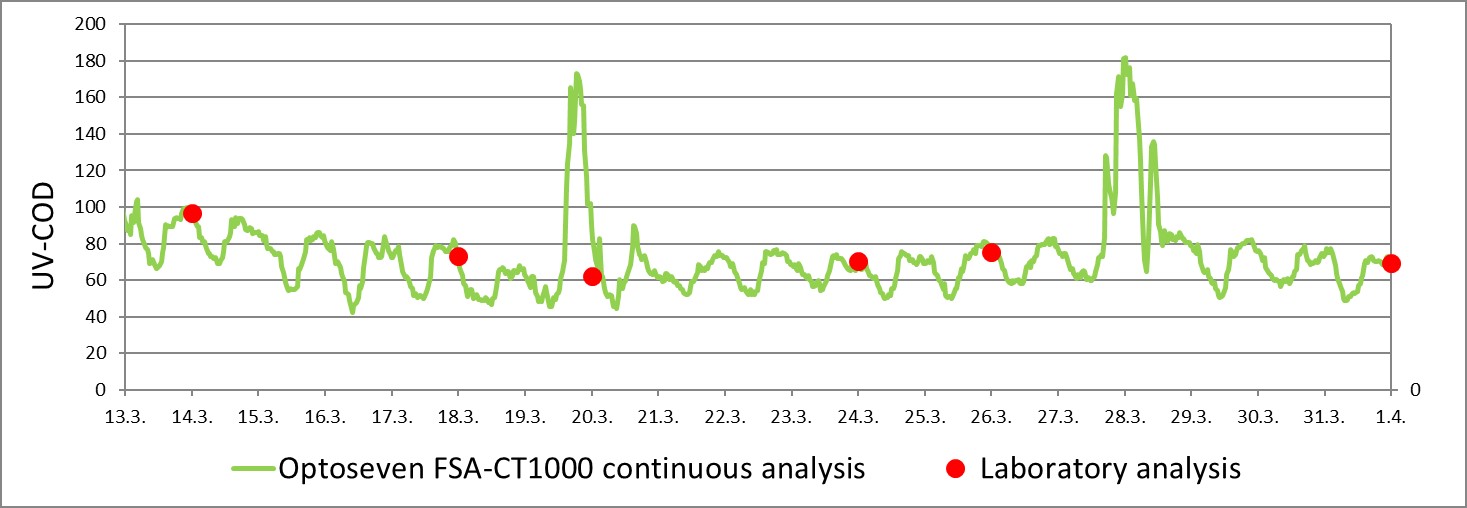

Waste water UV COD analysis

Optoseven Benefits

Low Cost of Ownership

No expensive wearing parts, manual cleaning or other maintenance needed. Multiport measurement with single analyzer.

Non drifting design

Optical measurement method with automatic cleanin, zero calibration adjustment and self-diagnostics.

Wide measuring range

Measuring range from deionised water to the influent waste water on a single analyzer unit.

Custom solutions

Flexible analyzer platform can be tailored to measure custom components in new applications.

News

Applicability of online COD-analyser for different waters

Maija Salonen, Master’s programme in Water Technology, Master’s Thesis, Lappeenranta–Lahti University of Technology LUT School of Engineering Science.

Optoseven participates in the Pulp & Beyond 2024 exhibition

Pulp & Beyond 2024 exhibition at Helsinki Expo and Convention Centre 10-11 April 2024. Pulp & Beyond is the leading forum bringing together the latest

Continuous lignin measurement

We have developed a continuous and reagent-free measurement of dissolved lignin in liquids.